To inquire about adhesives, coatings and specialty formulations, please contact 3 Sigma.

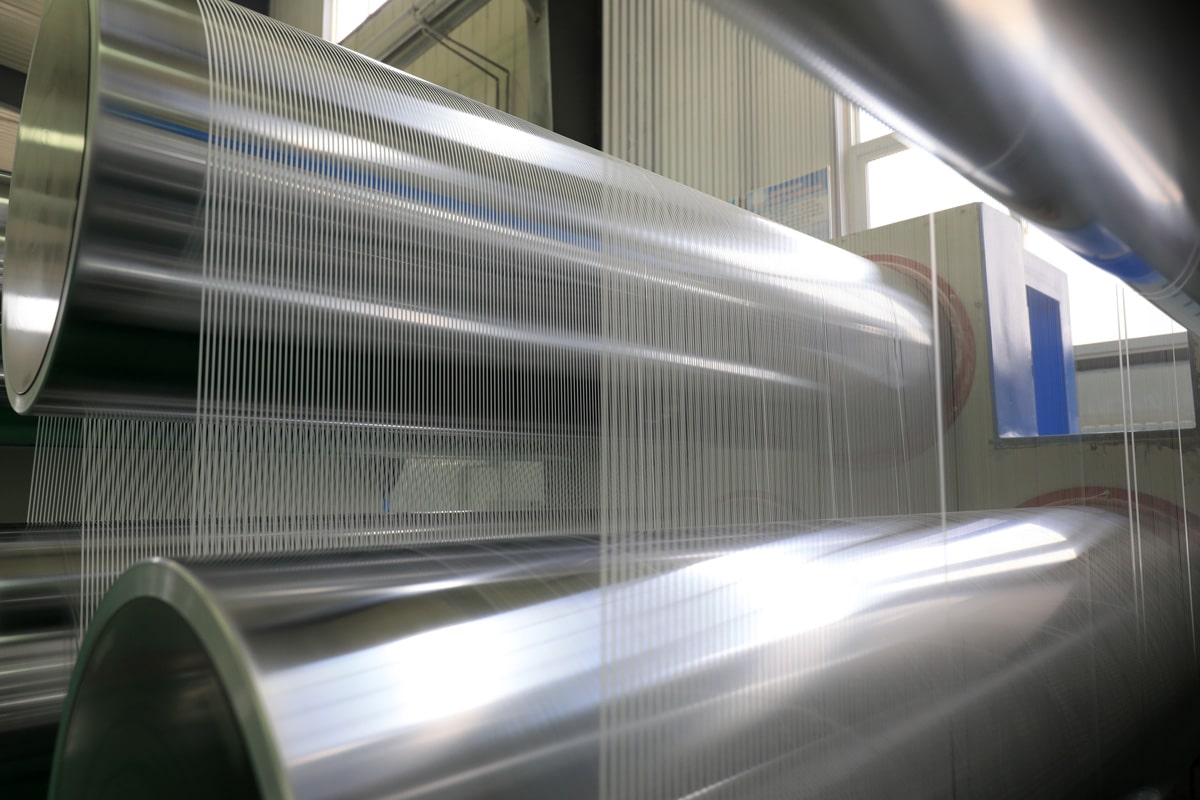

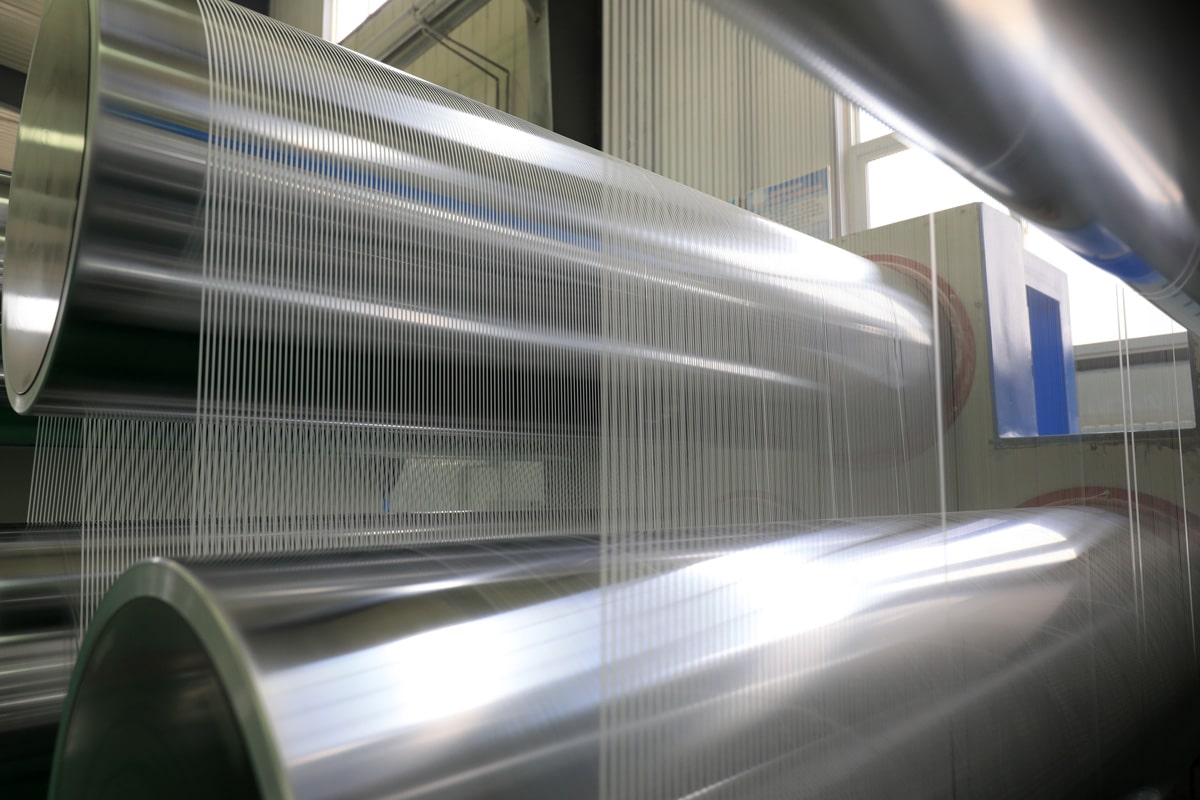

Equipment

Equipment for Adhesives, Coatings, Specialty Formulations

3 Sigma’s Adhesives Coating Versatility

3 Sigma’s manufacturing line can produce a wide range of adhesive coatings with multiple coating lines and methods, providing their customers with top-of-the-line products, service, and results. 3 Sigma’s associates are specially trained to handle a considerable number of job changeovers and setups to rapidly meet custom product production in a concise amount of time.

3 Sigma is one of the few companies that offer hot-melt, emulsion, and solvent-based adhesives under one roof in the pressure industry.

Equipment Specializations

- Hot melt adhesive coatings range from 3” to 20” web width (6 coating lines)

- Solvent-based adhesive coatings from 10” to 65” web width (2 coating lines)

- Emulsion-based adhesive coatings from 10” to 80” web width (4 coating lines)

- Specialty coatings (depending upon formulations) from 3” to 80” web width

- Four slitters ranging from 42” to 80” in width, two re-winders (16” and 24” max-width)

- Pattern Coating for gummed and dry areas as narrow as ¼” with 1/16” tolerance

- Dual-adhesive coatings on the same web (constructions with two different adhesives)

- Specialty formulations and compounding for a wide range of applications

- Multiple coating process technologies: gap, slot die, Mayer rod, gravure

What Does This Manufacturing Versatility Provide?

- More design options

- Faster lead times

- Increased opportunities

There is a strong belief at 3 Sigma that the key to success in most markets today is to be innovative and quick in production, without sacrificing quality. 3 Sigma helps customers achieve this by being reliable, consistent and providing top-notch customer service.